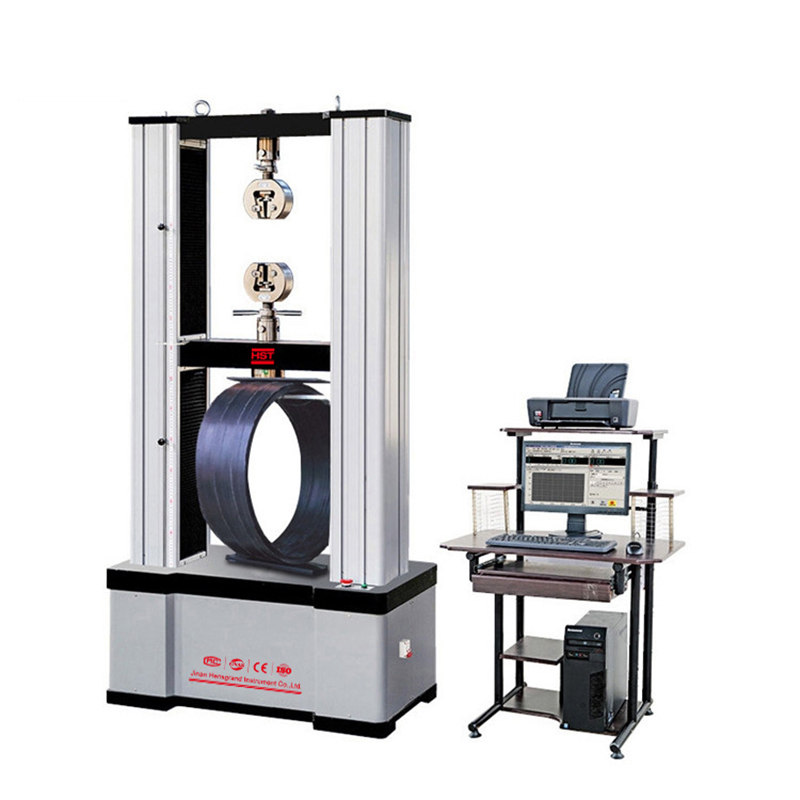

WDW-10E Electronic Universal Testing Machine

WDW-10E Electronic Universal Testing Machine

Application

It is applicable for wide range of material for tension, compression, bending, shearing and low cycle Test.Suitable for metal, rubber, plastic, spring, textile, Organic / Inorganic and components Testing. It is widely used in the corresponding industries, research and development, test institutes and training centers etc.

Standards

ASTMA370, ASTME4, ASTME8, ASTME9, ISO6892, ISO7438, ISO7500-1, EN10002-4, GB/T228-2002,GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.

Safety Divice

Stroke protection: Machinery,computer double protection, prevent over preset

Force protection: system setting

Emergency stop device: handing emergencies

Force protection: system setting

Emergency stop device: handing emergencies

General installation conditions and energy medium requirements

1. Temperature within the range 0c~50c

2. Temperature of work area the range is 0-55c

3. Relative humidity lower than 95%

4. Noise level 25 DB

5. In an environment without obvious magnetic interference and surrounding non-corrosive media

6. In a shock-free, vibration-free environment

7. Leave space not less than 0.7m around the Tester, clean and dust-free work environment

8. The base and rack are properly installed on a solid level base

9. Power supply: 80-220V±10% 50Hz 5 A

2. Temperature of work area the range is 0-55c

3. Relative humidity lower than 95%

4. Noise level 25 DB

5. In an environment without obvious magnetic interference and surrounding non-corrosive media

6. In a shock-free, vibration-free environment

7. Leave space not less than 0.7m around the Tester, clean and dust-free work environment

8. The base and rack are properly installed on a solid level base

9. Power supply: 80-220V±10% 50Hz 5 A

Specifications

1. Package: Fumigated wooden case

2. Dimension(mm): 740*420*1720

3. Packing size(mm): 910*530*1890

4. Crated weight(kg): 340

5. Lead time: 15 working days

2. Dimension(mm): 740*420*1720

3. Packing size(mm): 910*530*1890

4. Crated weight(kg): 340

5. Lead time: 15 working days

| Model: | WDW-10 |

| Structure: | Double column double spaces |

| Max. Load(kN): | 10 |

| Material: | All aluminum alloy surface spray painting shell |

| Load accuracy: | ISO 7500 Class 1/ Class 0.5 |

| Load resolution: | 1/ 30000 |

| Resolution of displacement: | 0.01mm (250mm) |

| Test speed(mm/min): | 0.05-1000 stepless arbitrary setting |

| Speed accuracy: | within ±0.5% set speed |

|

Tensile space(mm):

|

800 (can be customized) |

| Compression space(mm): | 800 (can be customized) |

| Test width(mm): | 400 |

| Beam travel distance(mm): | 1140 |

| Workbench thickness(mm): | 30 |

| Base height(mm): | 210 |

| Power supply: | AC220V±10%,50Hz/60Hz(can be customized) |

Software :

1. English

2. Sample settings can be saved,changed and remembered

3. Examination of metal , plastic, minerals, organic and inorganic materials, fiber fabrics and textiles;

4. Display of one sample curve or support for multiple curve overlays;

5. Report in Excel, TXT, CSV, TAB format;

6. Load displacement, deformation and real-time testing flow

7. Dynamic display;

8. Device management and monitoring locally as well as remotely via a web application;

9. Must be able to self-calibrate;

10. Disconnect function after completion of testing;

2. Sample settings can be saved,changed and remembered

3. Examination of metal , plastic, minerals, organic and inorganic materials, fiber fabrics and textiles;

4. Display of one sample curve or support for multiple curve overlays;

5. Report in Excel, TXT, CSV, TAB format;

6. Load displacement, deformation and real-time testing flow

7. Dynamic display;

8. Device management and monitoring locally as well as remotely via a web application;

9. Must be able to self-calibrate;

10. Disconnect function after completion of testing;

Load sensor

China or USA imported interface high precision dual direction sensor, high accuracy , stable property can

meet batch test requirement

Send an inquiry for this product

.jpg)